IVAL Hydronics UK Ltd

Empower The Future

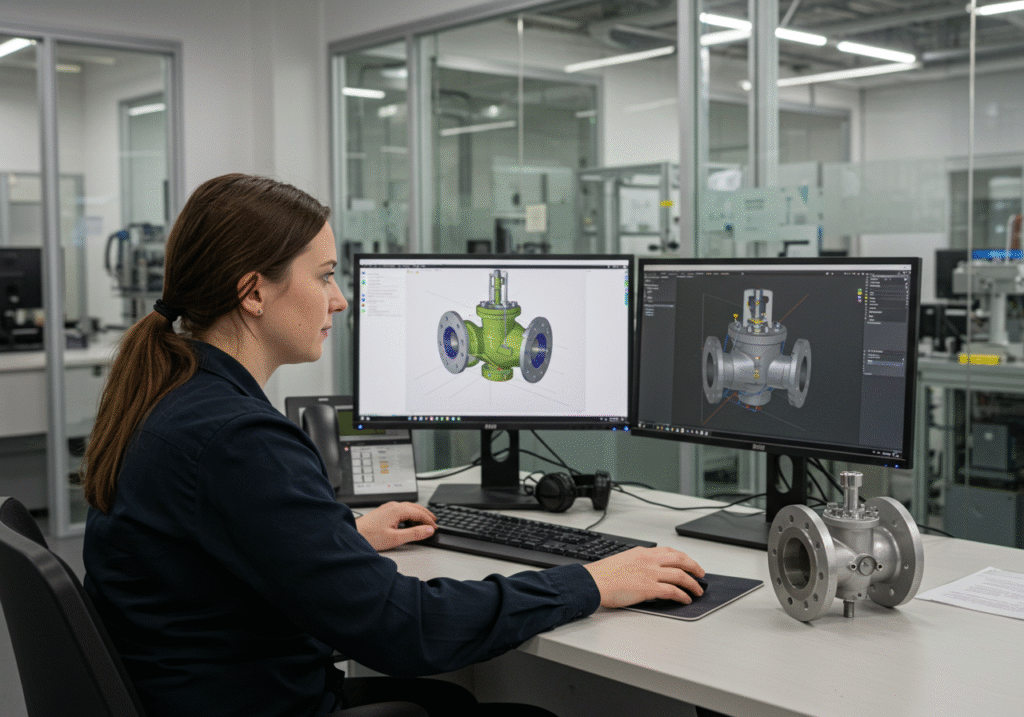

IVAL is a UK-based leader in water valves and accessories, known for precision engineering and reliable performance. We innovate to meet the evolving needs of residential, commercial, and industrial systems. With a focus on quality, sustainability, and customer-centric solutions,

Factory Highlights

Inside Our Factory

Sustainability

Committed to Delivering Safe, Reliable Water Control

At IVAL, we engineer every valve to ensure safety, reliability, and environmental responsibility. Our products support sustainable infrastructure and protect water systems around the world.

We Follow Best Practices

We use the highest-grade materials and cutting-edge manufacturing to deliver products that exceed industry standards

- Sustainablility

- On-Time Project Delivery

- Advanced Manufacturing Technology

- Innovative Product Design

Sustainability

Powering Infrastructure, Preserving the Future

At IVAL, we are committed to developing high-performance water valves that meet today’s infrastructure demands while protecting tomorrow’s environment. Our solutions are designed with durability, efficiency, and sustainability at their core—helping build stronger, more resilient communities across the globe.

United Kingdom

71-75 Shelton Street , Covent Garden, London, United Kingdom ’ WC2H 9JQ

Engineered for Control:

Our Core Water Flow Solutions

Potable Water

Safe and reliable valves for clean water distribution systems in residential and industrial applications

Hydronics

Pressure-balanced valve systems designed for efficient fluid control across various infrastructures.

System Control

Intelligent valve systems to control pressure and flow, ensuring efficient performance and minimizing water loss.

Our Latest Works

SKYTRAIL

New York, USA

GRAVITON

SYSTEMS

Malmo, SE

LUMEXA

Toronto, CA

ARDENTIX

Athens, GR

Request a Quote

Ready to work with industry-leading water valve experts?

Frequently Asked Questions

Strainers should be positioned to protect key equipment and to maintain the overall efficiency of the system by preventing the accumulation of debris in heat emitters such as terminal units (e.g., fan coil units).

When intended to safeguard major components like boilers, chillers, or pumps, strainers must be installed upstream of the equipment. This ensures that large particles carried by the circulating water are filtered out before reaching and potentially damaging these components.

Additionally, strainers can be placed at strategic points in the system—such as at branch lines or within each terminal sub-circuit—to capture smaller particles and prevent them from entering terminal units, which could otherwise reduce their performance.

The pressure drop across a valve depends on the flow rate passing through it—the higher the flow rate, the greater the pressure drop, and vice versa.

To help calculate this, manufacturers provide a Flow Coefficient value. This coefficient allows engineers to estimate the pressure drop for a given flow.

For metric units (e.g., m³/h and bar, or l/s and kPa), the coefficient is denoted as Kv.

For imperial units (e.g., gallons per minute [gpm] and PSI), the coefficient is known as Cv.

Since liters per second (l/s) and kilopascals (kPa) are commonly used, we’ll focus on Kv.

The formula for calculating pressure drop is: Δp = (36Q/Kv)2

Where:

1. Δp = pressure drop (kPa)

2. Q = flow rate (l/s)

3. Kv = flow coefficient (no units)

We ship worldwide with efficient logistics and tailored support for regional regulations.

FODRV stands for Fixed Orifice Double Regulating Valve, while VODRV refers to a Variable Orifice Double Regulating Valve.

The key difference lies in the type of orifice through which water flows:

FODRV (Fixed Orifice):

The pressure drop is created by a permanently fixed orifice—a static opening of set dimensions. As a result, the flow coefficient (Kv) is constant and typically referred to as Kvs.

This consistency ensures high measurement accuracy (±5%), regardless of the valve’s handwheel position.VODRV (Variable Orifice):

Here, the orifice is formed by the seat/disc assembly. The gap between them changes as the handwheel is adjusted, meaning the Kv value varies depending on the valve’s opening.

This results in accurate measurement (±5%) only when fully open, but accuracy drops (to around ±18%) as the valve approaches minimum opening (e.g., 25% open), as per CIBSE recommendations.

In practice:

FODRVs are preferred by commissioning engineers because the pressure drop can be pre-calculated based on a known Kvs value, simplifying system balancing.

VODRVs, on the other hand, require recalculation of pressure drop on-site whenever the handwheel setting changes, making the commissioning process more complex.

The primary difference between grey cast iron (commonly referred to simply as cast iron) and ductile iron lies in their graphite structure, which is influenced by the addition of trace elements during production.

Grey cast iron contains randomly distributed flake-shaped graphite, which makes the material more brittle and less ductile.

Ductile iron, on the other hand, includes a trace amount of magnesium or other nodulizing elements. This transforms the graphite into spherical (nodular) shapes, resulting in significantly improved mechanical strength and ductility, while still offering similar levels of corrosion and wear resistance.

Both materials are widely accepted for valve manufacturing:

Grey cast iron complies with EN 1561

Ductile iron complies with EN 1563

Crane valves are manufactured in accordance with relevant design standards, which specify approved grades of cast and ductile iron to comply with these standards and with the Pressure Equipment Directive (PED).

Material selection for valves is influenced by several factors, including the manufacturing process, valve size, and required pressure rating.